Thermographic printing, an application of thermography, is a relatively recent method compared with classical, true embossing. The process was developed in the USA and came shortly thereafter to Europe.

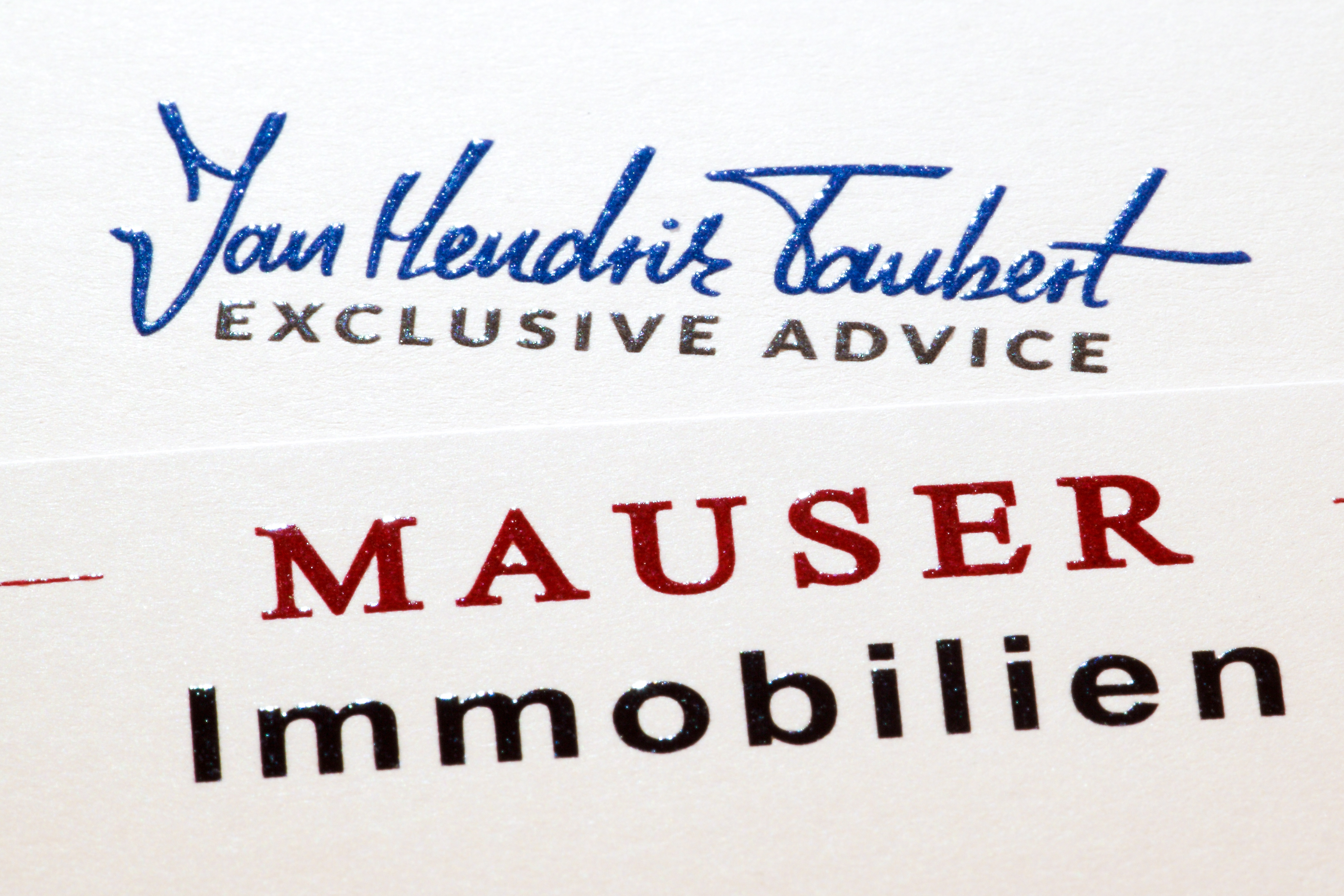

Sometimes the expression “imitation engraving” can be heard instead of the term thermographic printing. This is basically incorrect, because neither the process nor the results can be compared with real steel engraving.

Thermographic printing is a process of its own that can be successfully implemented in specific areas that need to be defined exactly.

The process is somewhat more economical as original steel engraving, since no special tools are necessary for attaining the desired effect. Thermographic printing doesn’t quite attain to the elegance of steel engraving, however. It comes close to it, but can never become a substitute for a steel-engraved print.

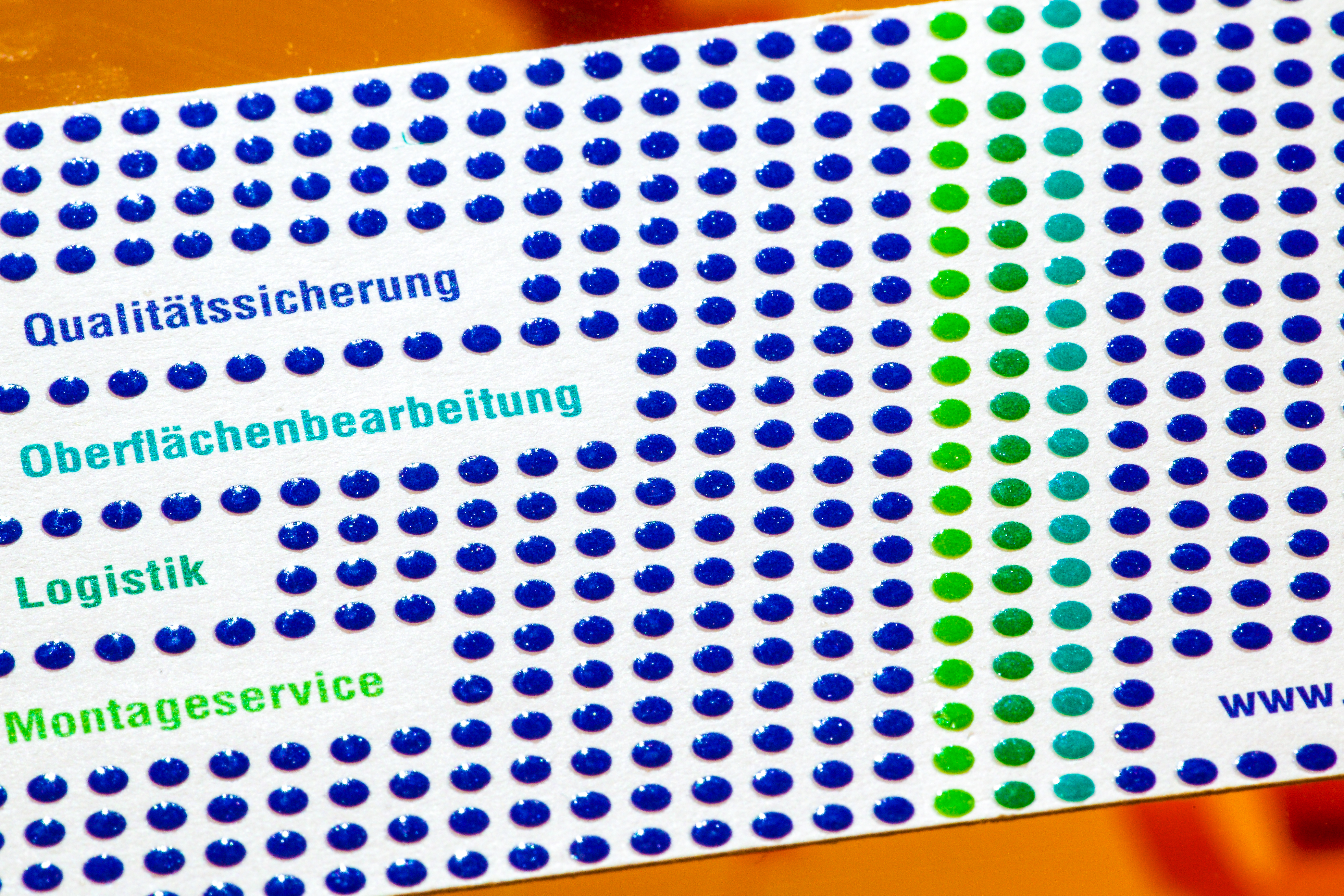

A considerable difference to die stamping in general is that thermographic printing requires preselecting a grain size for a particular print job, which sets the relief height as a result. The relief height then becomes a constant throughout the print job, regardless if wide or narrow lines are in the typeface or in the emblem. Thus, the dynamics of a genuine steel-engraving are inevitably missing.

The print acquires its relief subsequently through special intermediate processing, which lends it a somewhat steel-engraved appearance.

Thermographic printing is not normally adapted for laser printers. Today it is possible to prepare the thermographic prints accordingly, but they lose somewhat on brilliance.

A general laser printer guarantee cannot be given, however. To be on the safe side, it is better that you have us send you some test sheets that you can try out on your printer to see if the relief withstands the heat produced by the printer.

On the other hand, this printing process is quite advantageous for calling cards, greeting cards, shelving labels and the like.

The designer has many interesting opportunities open to him. This process, too, can be combined widely with other printing processes.